Warning - This trick does not work well for high speeds. Removing and replacing the rubber seals results in an imperfect seal. At high speed, centrifugal force causes the conductive grease to fly out of the bearing. For high speeds, encasing the bearing in a hard material such as epoxy might help.

I needed bearings that conducted electricity. My tests showed that if a bearing was not spinning then it had a low resistance. If I spun it, however, it had about 20Mohm resistance which is basically infinite. Pictures are shown below of how I tested this.

To make bearings conduct I took ordinary bearings, removed the rubber seals from either side, removed as much of the grease that came with it as I could and put conductive grease in its place. The resistance went from 20Mohm with the original grease to about 200ohm to 500ohm across two bearings with the conductive grease. So for one bearing the resistance during rotation was about 100 to 250ohm. See below for more about how the measurements were made.

Note that the first time I did it the results weren't so good (about 250kohm). This was probably because the first time I did it (October 14) I just used my xacto knife to pick out the original oil so undoubtably there was some left. This time (October 19) I removed all oil by removing the seals and putting the now opened bearings in a container of degreasing fluid available from automotive supply stores (I used MotoMaster Dunk Degreaser). I left them in it for about 10 minutes and then ran high pressure hot water from the kitchen sink through them and then repeated the whole procedure a second time. In the end there was no sign of oil (in fact one was a bit squeaky when turned by hand). I then put in the conductive grease. This time the results were in the 100ohm to 250ohm range for a single bearing.

|

|

|

Testing the conductive bearing

I wanted to minimize any eddy currents and triboelectric effects from interfering with my measurements so I measured across a spinning metal shaft using two bearings. I held the outside of the bearings against the shaft so that it would spin freely with the shaft. The inside of the bearing did not spin at all. The result was that no parts were scraping against each other. I tested before changing the grease and then again after.

|

|

|

|

| ||

|

|

|

The reading on the meters fluctuated a lot probably due to the fact that the bearings were being held in place by hand and that the shaft was wobbling during rotation. Note that this measurement was made across both bearings so divide by two for a single bearing. Resistance without rotation was in the single digit range so it is lost in the variation in resistance observed during rotation.

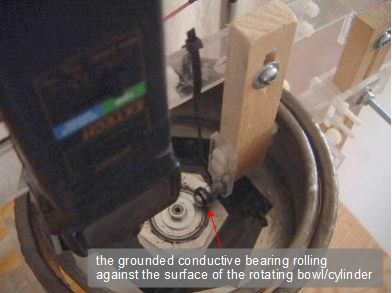

Using the conductive bearing for grounding with high voltage

I later used this conductive bearing trick to ground a part of a capacitor that was rotating at very high speed, up to 8400 RPM. The other side of the capacitor was stationary wand was the high voltage side. The whole capacitor had around 14kV across it.

Details of this rotating charged cylinder, non-conventional propulsion experiment can be found here.

|

|