Solar snow pre-melter experiments

This is an attempt to find a way to quickly melt a hole through snow, exposing an area of a solar panel at the beginning of a sunny day so that the solar panel itself can take over melting snow from there. Solar panels, typically photovoltaic/solar power panels, that are mounted on a shallow angle and are inaccessable during the winter can become covered in snow for long periods of time during which they will produce no power.

January 14, 2011 - 1st Snow pre-melter experiments

Two different methods were tried. The 2nd panel from the left has a black exposed plate connected above it. The 4th panel has 5 black coat hanger wires sticking up. The other two panels acted as controls for the experiment. After a day of sunshine, no noticable melting had occurred. This was likely because most of the heat that was converted from sunlight in the collecting surfaces was lost to the surrounding cold air. The outdoor temperature was -9C (16F), -16C (3F) with the windchill factor.

February 3, 2011 - 2nd Snow pre-melter experiment (insulated collector)

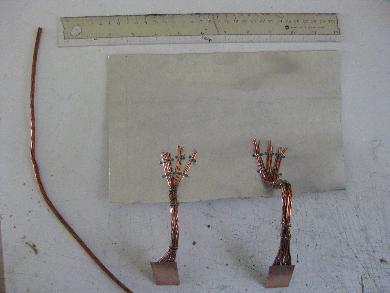

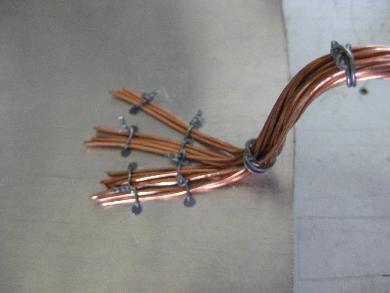

Using lessons learned from the 1st attempt above I made a new flat plate collector that was fully insulated. Heat was transfered to the test panel using two heat transfer columns which consisted of very thick stranded copper wire. Care was taken even to insulate the top lengths of the columns. The bottoms of the columns were two copper plates for making contact with and transfering heat to the panel.

Click on the captions for larger photos.

Results

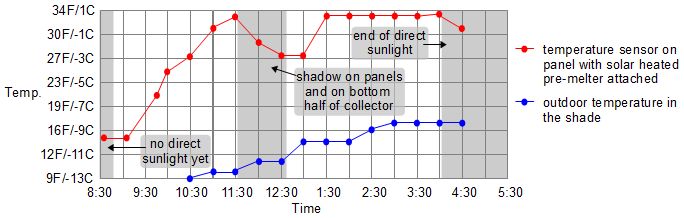

There was sun the entire day. The following chart shows the temperatures measured on the test panel as shown in the above-left photo. You can see that for a substantial amount of time the panel temperature was above freezing. Unfortunately I didn't have a second remote temperature sensor for the control panel but as you'll read below, just checking the snow with my fingers at the end of the day showed that no melting went on with the control panel.

The only really visible changes during the day were around the heat transfer columns as the following two photos show.

However, at 4:30pm I dug into the snow with my fingers to see what the snow was like just above the panels. The snow for the control panel (the one with no collector) was uniformly powdery throughout. The snow for the panel with the pre-melt collector was crystalized for the last few millimeters above the panel surface and this was the case over the entire area of the panel as if either melting had gone on over the entire panel surface or melting had gone on near the top and dripped down over the panel. This crystalization is consistent with the warmer than freezing temperatures measured by the temperature sensor.

Conclusion

The object of all this is to quickly expose a small area of solar panel at the beginning of a sunny day so that the darkness of the panel can spend the rest of the day melting snow on its own. So far I haven't acheived that.

Two basic approaches: melting from bottom upward or melting from top down. The 1st pre-melter above tried the top down approach. This 2nd pre-melter tried to melt snow from the bottom up. A lot of heat went to the panel and spread throughout the panel. This was probably a waste since the idea is to quickly melt a hole and let the panel take over turning sunlight into heat from there. However, this 2nd one also did a bit of top down too, since more than just the bottom plate of the heat transfer column was exposed, resulting in more melting around the columns.

One big problem with a top down approach though is that if more of the heat column were uninsulated then as more of it was exposed to cold outside air, more and more heat loss would occur to the air. A very important fact is that the larger the temperature difference the greater the heat transfer efficiency. So more heat would be transfered where an uninsulated column is in contact with -11C (12F) air than where an uninsulated plate is in contact with -1C (30F) snow just above a warmed solar panel.