These gravitators were made of MotoMaster resin usually used for

making automotive body repairs. From outward appearances they

are 12"x3"x3" solid blocks of resin with a wire sticking out

from each end.

They were made by first using a mold to make a .5 inch thick block

of resin. The mold was made using 1/8 inch thick plastic for the

sides and an aluminum plate for the base, all taped together with black

electrical tape.

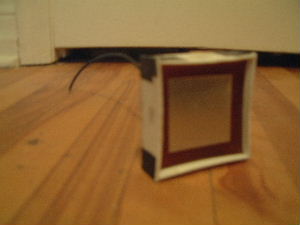

Once the resin block was complete, a hole was then drilled through

the center to admit

the electrode wire. A wire was then soldered to an electrode plate.

The wire was then put through the hole and a little resin was put

on the block around the hole. The plate was then gently pulled down

onto the still wet resin and the whole thing allowed to dry.

Electrode glued to end piece - rear view

|

|

Electrode glued to end piece - top view

|

|

After two such end pieces were made, the aluminum plate base of the

mold was then removed leaving just the plastic sides. The sides were

taped to near the top of the resin blocks so that together they formed

a new mold and the building up of layers began.

Note that only thin layers of 1/8 inch or so were poured at a time

since as the resin dries it produces a lot of heat. Too much heat and

it melts the plastic mold and make a convex bowl-like surface with convex

sides too.

Two end pieces beginning buildup

|

|

Due to resin's toxicity, this construction was all done in a specially

built Resin Construction Unit

;->.

Resin Construction Unit

|

|

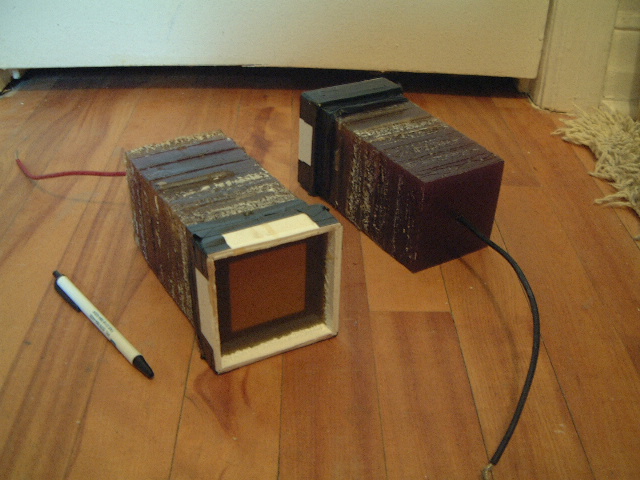

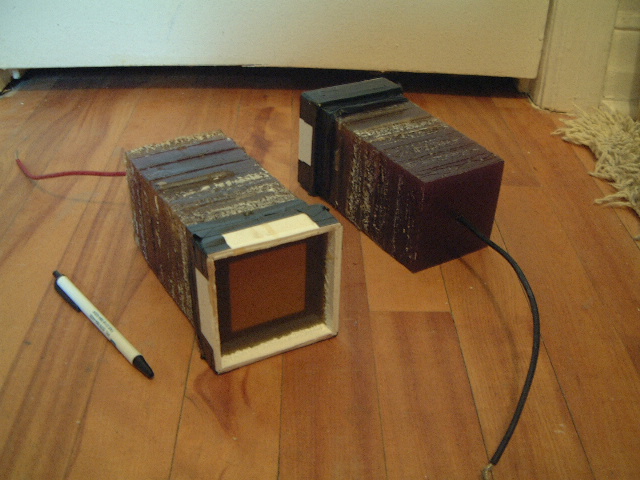

Eventually enough layers were built up to make two 6 inch halves.

Completed two halves

|

|

The two halves were joined.

Joining the two halves

|

|

Next, a thin layer (about 1/8 inch thick) of parafin wax was poured onto

the sides for extra insulation.

Joined halves

|

|

Pouring wax

|

|

Completed waxed gravitator

|

|

Done.