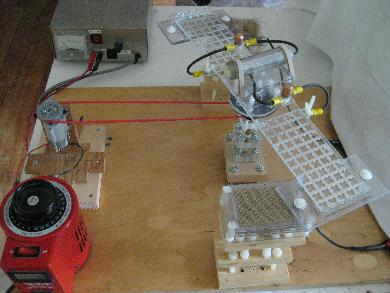

For my testatika and

my vacuum energy tapping

experiments I needed a rotating arm or disk with the following features:

- adjustablity to get rid of wobble

- able to distribute high voltage to segments and parts mounted

to the arm or disk

- very adjustable way of having parts that faced the arm or

disk but that did not rotate

Basically, since I can't make precision parts I had to make

something with the correct adjustablity to make up for the lack

of precision. This is what I came up with.

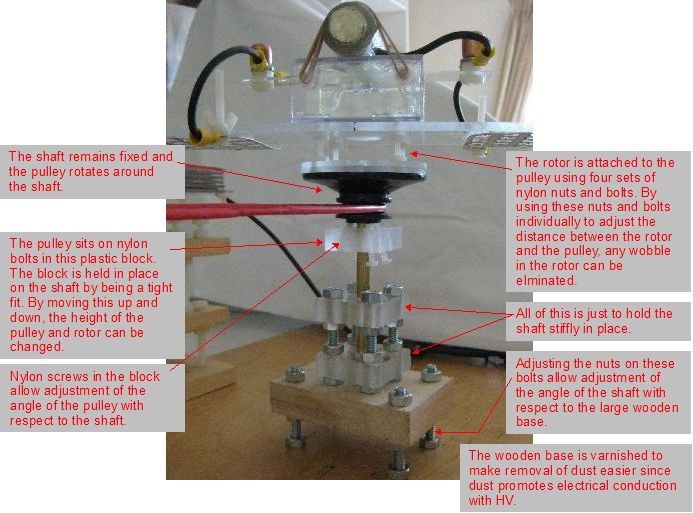

Adjusting the rotor

The pulley belt

The pulley belt is a long length of heatshrink tube normally

used for adding electrical insulation to wires. The following

video shows how it was made.

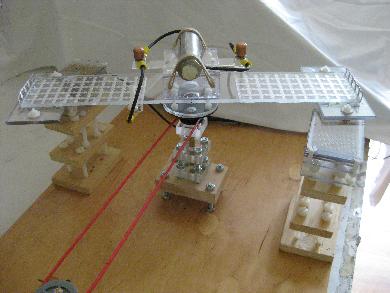

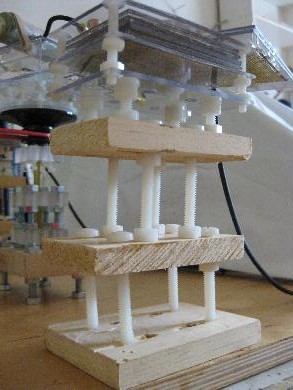

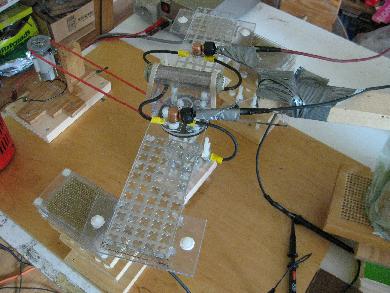

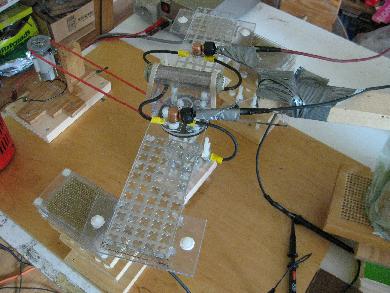

Towers for parts facing the rotor

A problem I've had in the past was how to have infinite adjustability

in the position of objects facing the rotor. This horizontal layout

was chosen to solve that problem. The towers shown below support

parts facing the rotor. Using all the various nuts and bolts, the tilt

and height can be adjusted and by sliding the towers around horizontally

on the wooden base, their location with respect to each other and

the parts on the rotor can easily be changed.

A sample rotor

Using the above basic structure, pretty much any rotor can be

used. I even left room for one that is a complete disk.

As an example, the following subsections contain details

of the first one I made for this structure, illustrating what

I hope are some useful ideas for adjustablity and charging.

The original purpose for this rotor was to search for the

principle behind

testatika principle experiment though I've used it for

other things as well.

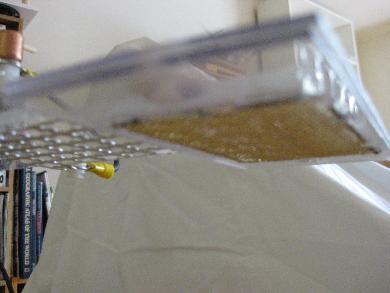

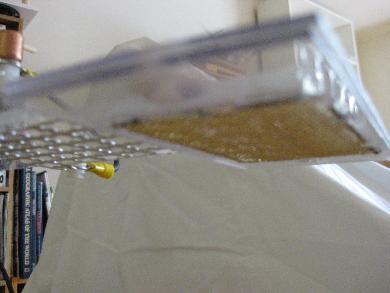

Adjustable end plates

A brass mesh glued under the bottom plate.

|

|

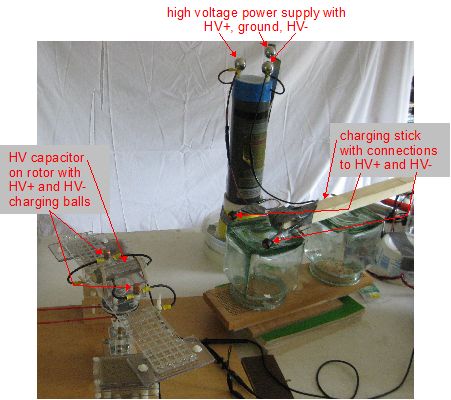

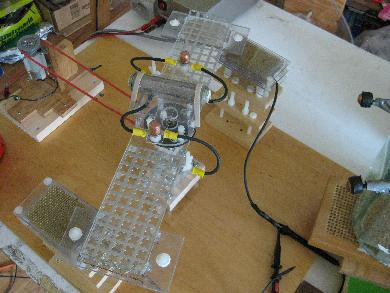

How it's charged

As shown below, the rotor carries its own high voltage in the form

of a homemade high voltage capacitor. A charging stick was made

that has two balls on it, each of which is wired to

my positive/negative high

voltage power supply.

Before starting rotation, the the two balls on the charging stick in

contact with two smooth surfaced balls mounted on either side of

the capacitor, each of which is wired to one plate of the capacitor.

The charging stick's balls in contact

with the balls on the rotor during charging.

|

|

Charging complete. The charging stick is moved away.

|

|

The homemade HV capacitor

The HV capacitor consists of an inner copper cylinder cut from a half

inch hollow pipe, around which is a sheet of polyethylene wrapped around

a few times, followed by a thin sheet of copper. All of this is wrapped

with acrylic sheets and further encased in epoxy and plastic endcaps.

From the web, the breakdown voltage of polyethylene is 25kV/mm so I

wrapped enough polyethylene to make up just over 1mm thick. The

capacitance is 39pF. Click on the photos below for larger versions.

The capacitor is held onto the rotor with rubber bands and so that it can

easily be replaced with another.

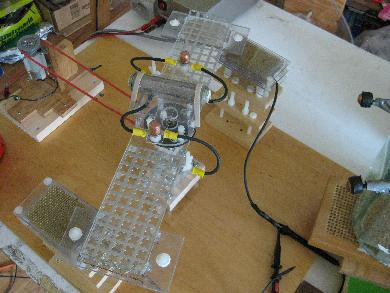

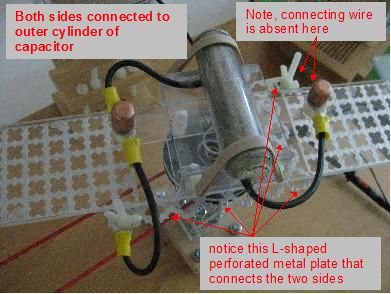

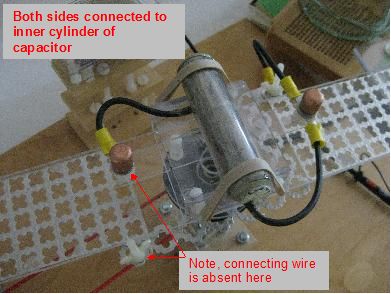

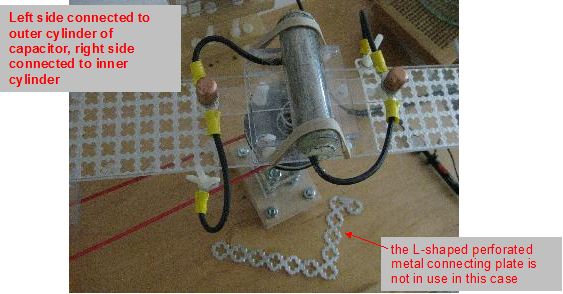

Selecting the polarities for the rotor

I wanted to be able to have the following options for the polarities

of the parts on the two ends of the rotor arm:

- both HV positive,

- both HV negative, or

- one HV positive and the other HV negative.

The following photos illustrate how that's done. The first two are

actually redundant since the cylinders of the capacitor can be

charged either way: outer cylinder HV+ and inner cylinder HV-, or

outer cylinder HV- and inner cylinder HV+.