All tests were done with the Low Friction PVC Stator/Rotor.

First tests - didn't move other than due to Coulomb forces (Sep. 7, 2005)

|

|

|

|

|

I tried with the coil positioned 10cm from the needles and 8.5cm from the needles. I turned the voltage all the way up to 57kV at which point the current was around 50uA. I tried with the rotor in various starting positions with respect to the stator. Given this high current I figured there was no point in raising the voltage higher. At no time did the rotor move. My guess was that the rotor was too heavy so I switched to a lighter rotor (see next).

|

|

|

I tried all the same things as with the heavy rotor and got the same null results.

I then switched the polarity such that the needles were now grounded and the coils were high voltage positive. This makes sense since the needles are sharp points embedded in the wax next to the wick whereas the coil is made of 18AWG wire or thicker and is fully insulated with no sharp points. This turned out to be the case as I was now able to turn the voltage all the way up to 75kV (the most my power supply could do) with only around 15uA of current. See the following picture.

|

|

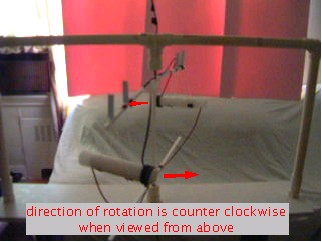

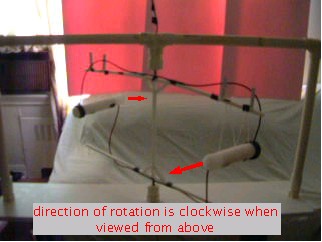

I got movement! BUT... only at certain positions along the arc of rotation and in both directions depending on where it was when voltage was applied. Also, it would do so only at around 75kV, so very very high voltage was needed. The most likely reason is coulomb forces - attraction and repulsion balancing out. See the following.

Click on the above pictures for QuickTime movies of the movement (approximately 1.5Meg each). If you don't have QuickTime you can download it here.

The likely explanation is that when the rotor arm is close to 90 degrees then the high voltage wires that follow the rotor arm on either side interact unevenly with the stator bar above them in terms of electrostatic attraction and repulsion. The closest way to balance out is to rotate the remaining amount to 90 degrees with respect to the stator bar when the forces will then be balanced. The reason the same thing doesn't happen when the polarity is reversed is that with the high voltage on the needles instead of on the coil, there is too much current flowing to get the voltage up to 75kV.

In any case, the result is that the candle devices themselves are not producing any noticable thrust.