I needed some way to remotely control my

BB-8 droid at a very low cost

and I also wanted to use an Arduino to do speed control

using Pulse Width Modulation (PWM). So I bought a remote control

toy truck at a yard sale and hacked together a circuit to convert

the remote control's output to something the Arduino would understand.

Note that I later removed this and replaced it with a far more compact,

flexible and longer communication distance method using

an HC-05 board that allows me to control the BB-8 from my phone

over Bluetooth.

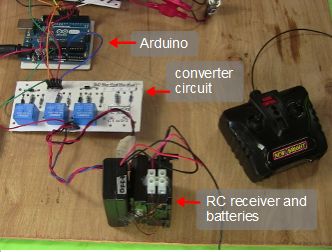

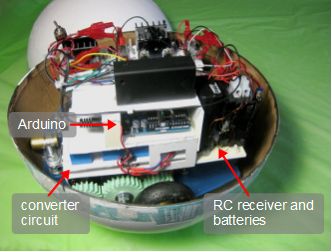

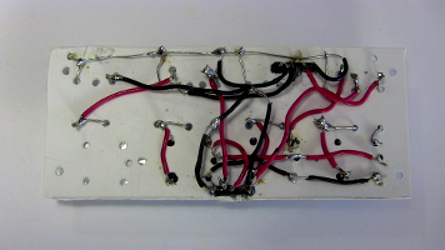

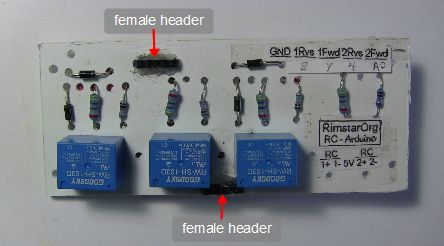

RC receiver to Arduino converter circuit.

|

|

|

RC toy truck and controller.

|

|

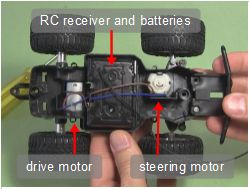

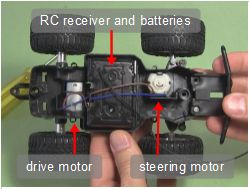

Top of truck removed.

|

|

As shown above, the central part of the truck was an RC receiver and

batteries. Two wires came out of that to go the the drive motor and

two more wires came out to go to the steering motor.

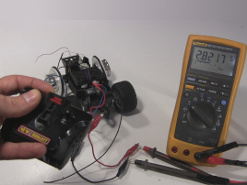

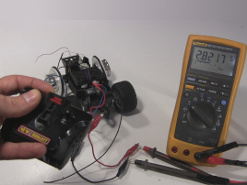

From testing shown below, both sets of wires produced the same outputs when

being controlled. When a stick on the remote

control was pushed up or to the right, depending on which stick,

a set of RC receiver wires put out a positive voltage, around 2.8 volts.

When a stick on the remote control was pushed down or to the left,

a set of RC receiver wires put out a negative voltage, around -2.8 volts.

Note that the voltages were either fully 2.8 or -2.8 volts, or 0 volts.

There was no gradual change. It was either on or off, meaning I wouldn't

be able to control motor speed using the remote controller, only

rotate the motors in either direction or turn them off.

They're basically on/off switches.

Remote control sticks: drive and steer

|

|

Testing RC receiver output.

|

|

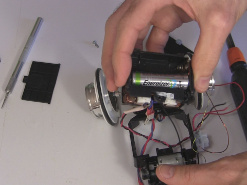

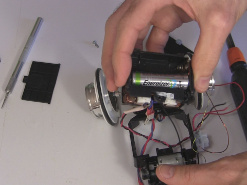

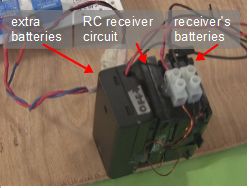

I didn't need the whole toy truck or its motors so, as shown below,

it was a simple matter of removing one screw and then using some gentle

pressure to snap the central part from the toy truck out, that being

the RC receiver and the battery case attached to it. The batteries were

2 AA batteries connected in series. But to get a longer battery life

I hot glued on a second battery case, also with 2 AA batteries in series,

and then paralleled that set with the first set.

Removing RC receiver from truck.

|

|

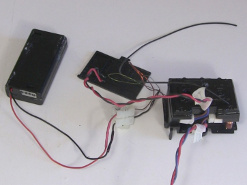

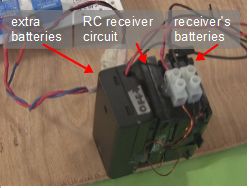

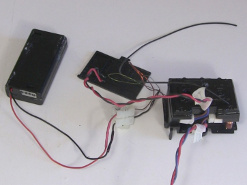

Extra batteries case and RC receiver.

|

|

Extra batteries case and RC receiver.

|

|

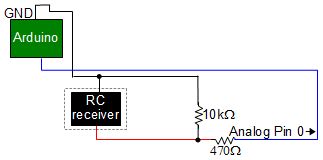

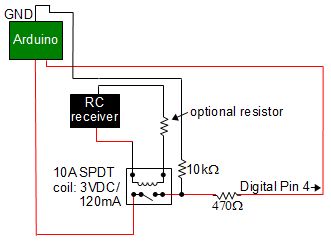

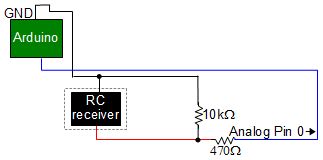

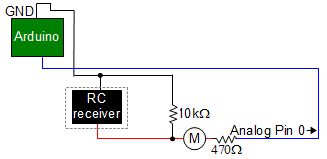

Next came figuring out a circuit to convert the 2.8V and -2.8V from the

RC receiver to things that the Arduino could understand. The following

is the high-level diagram of what ended up being done. Notice that in

some cases the 2.8V and -2.8V were converted to 5V except one case

where the 2.8V was given to the Arduino unchanged. The sections

below explain the circuit in detail.

RC receiver to Arduino high-level diagram.

|

|

Handling the 2.8V from the RC receiver

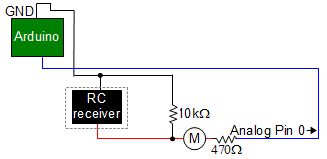

Handling the 2.8V was easy. The Arduino has analog input pins that accept

from 0V to 5V. The Arduino the converts that to a number from

0 to 1023 (0 for 0V and 1023 for 5V) which your Arduino program can get

using the AnalogRead() function. Here's the part of the circuit for

handling the 2.8V. But be careful. Those analog input pins can handle at

most 20mA of DC current. Below is part of the circuit for handling the

2.8V only.

Simple analog input.

|

|

Why the 470 ohm resistor? As I said above, the Arduino's analog input

pins can

handle at most 20mA of current. One way of limiting the current is

to run it through a resistor, and waste some of the energy as heat,

reducing the current that way. To know what size resistor to use I first

made sure I had new batteries in the RC receiver side of things.

I put a meter in series for measuring the current, as shown below,

and tried different sized resistors, starting with very large values.

Starting with large values resulted in current much lower than 20mA.

I tried lower and lower value resistors until I got something close to

20mA, but still less than 20mA. I settled on 470 ohms.

Position of the meter.

|

|

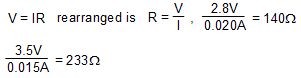

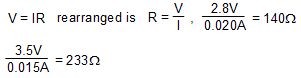

Instead of trying a bunch of different valued resistors, you can use

a potentiometer (variable resistor), provided you have one in a

suitable range. You can also get close by doing a simple calculation.

As shown below, ohms law states that V = IR, voltage equals the

current multiplied by the resistance. Rearranging to solve for the

resistance we get R = V/I, resistance equals the voltage divided by

the current. So 2.8V divided by 20mA gives a resistance of 140 ohms.

But suspecting that the maximum voltage might be higher than 2.8V and

wanting to keep the current safely below 20mA by a bit, you might

instead calculate 3.5V/15mA = 233 ohms.

Ohm's law calculations for current limiting resisance.

|

|

Why did I put a 10 kilohm resistor connected to ground in the above

circuit? That was so that when the RC receiver is off, any stray current

will go through the 10 kilohm resistor to ground instead of causing false

readings at the Arduino. This is called a pull-down resistor. I'm not sure

it's needed in this case. What effect does it have when the RC receiver

is on though? Since it's such a high resistance value, very little current

will go through it normally. The value, 10 kilohm, is a typical value

for this use.

Handling the -2.8V from the RC receiver

Handling the -2.8V was harder. That's because the Arduino doesn't

accept negative voltage for anything on any of it's input pins.

So I either had to turn the -2.8V into 2.8V or cause the -2.8V to

result in something else. I chose to do the latter.

If you give the Arduino 5V on one of its digital pins then if

you do a DigitalRead(Pin) then it will return HIGH. If the same pin

has 0V on it then it will return LOW. Luckily the Arduino has

a 5V source you can use for this purpose.

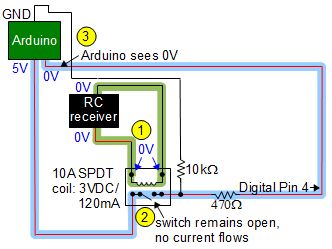

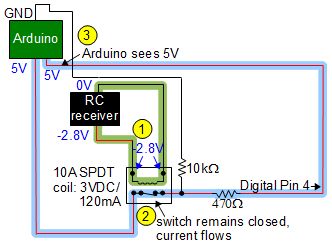

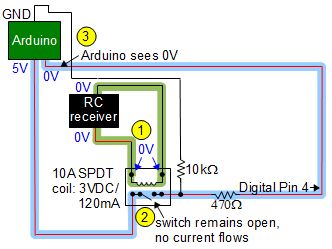

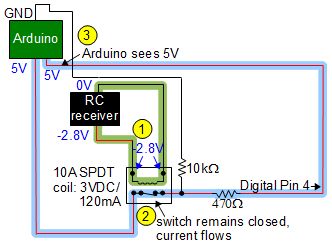

So I needed some way for -2.8V from the RC receiver to result in

one of the Arduino's digital pins getting 5V from the Arduino's own

5V source. One easy way to do that it using a relay, as shown below.

Relay not energized.

|

|

Relay energized with -2.8V.

|

|

In the first schematic above, this is what happens when there is 0V

from the RC receiver (see voltages shown in blue lettering.) The relay's

coil is not energized. You can tell this by looking at the switch in the

bottom part of the relay. The switch is open, meaning that no current

will flow through the path highlighted in blue. As a result, the Arduino

will see

0V at the pin that the circuit is connected to, digital pin 4 in this

case. This causes a call to DigitalRead(4) to return the value LOW, which

in this case means the remote control has not been activated and either

nothing should be done or something that was going on should be stopped.

With my BB-8 this indicates that a motor should be stopped.

But in the second schematic above, the relay is energized. The RC

receiver has put either 2.8V or -2.8V across the relay's coil,

it doesn't matter which. That closes the switch, connecting the two

parts highlighted in blue on either side of the switch.

The Arduino will now see 5V at digital pin 4.

This causes a call to DigitalRead(4) to return the value HIGH, which

in this case means the remote control has been activated and something

should be done. With my BB-8 this indicates that a motor should start

turning.

The 10 kilohm resistor is again there as a pull-down resistor. After

the relay's switch opens there may still be some stray noise on the

wire going to the Arduino's pin and voltage won't be 0V at the pin

as it should be.

With the 10 kilohm resistor, stray current will have a path

through the resistor to ground, pulling the voltage firmly down to

0V. But what about when the switch is closed? When the switch is closed

the 10 kilohms of resistance is so much higher than the practically

0 ohm resistance through the wire going to the Arduino's pin that

relatively no current will go through the 10 kilohm resistor path.

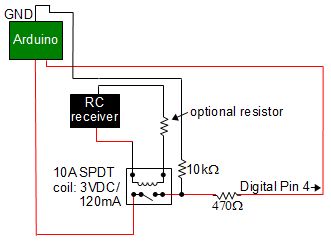

In the circuit below you can also see an optional resistor. You may

want to put one there in order to limit the current through the

relay's coil and, just as importantly, through the Arduino.

In my case I tried resistances here all the way down to

4.7ohms, but the current wouldn't close the relay with even that

resistance. Once I went to 0ohms here, i.e. no resistor, the relay closed.

The current was 70mA when it finally closed.

Optional resistor.

|

|

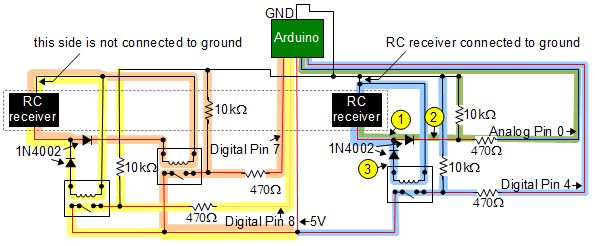

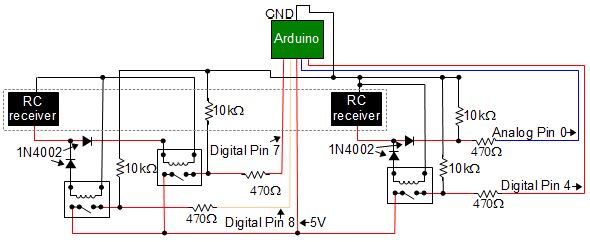

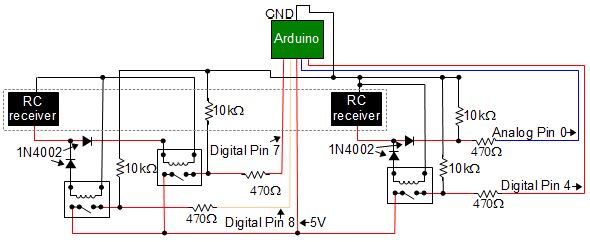

The complete circuit

Below is the complete circuit. Note the one simple sub-circuit highlighted

in green for taking 2.8V from the RC receiver and giving analog input to

the Arduino, as talked about above. Then note the three relay

sub-circuits highlighted in the other colors for taking either

2.8V or -2.8V and giving 5V to the Arduino, also as talked about above.

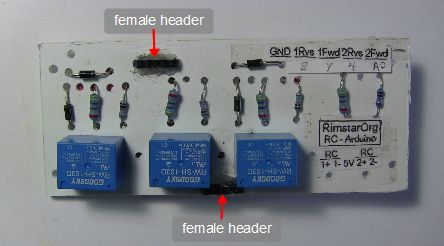

Here is the parts list for the RC receiver to Arduino converter board:

- resistors: 4 x 10kΏ, 4 x 470Ώ

- diodes: 4 x 1N4002

- relays: 3 x 10A SPDT, coil: 3VDC/120MA

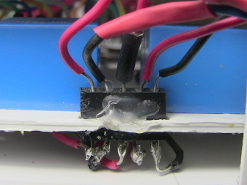

- female headers (pin headers): to plug wires into the board from

the RC receiver and to go to

the Arduino I put on some female headers. You can

buy a pack of 5 36-pin 0.1" female headers from

adafruit.com. You can see them labeled in a photo below

and a closeup in another photo below that.

Parts can be found in electronics stores, automotive stores, online,

and recycled from electronics that is being thrown out as garbage.

If you can't find the same part numbers as mine then look for

what are called equivalent parts.

The diodes - choosing which sub-circuits to use

Other things to note are the use of the 1N4002 diodes. As pointed out

near the top of this page, the RC receiver has two sets of wires

for output, one set for the driving motor and one set for the steering

motor. In the schematic below you can see the two sides, each with

two sub-circuits. On the left there are two relay sub-circuits (yellow

and orange) and on the right there is one relay sub-circuit (blue)

and a simple analog sub-circuit (green).

But something has to choose which sub-circuit to use on either side.

On the right side, when the bottom of the RC receiver is 2.8V there

will be 2.8V on the side of the diodes indicated by the number 1.

The sides of the diodes indicated by the 2 and 3 will be 0V. Notice that

the diodes are oriented in opposite ways. The one on the green path

is pointing away from the number 1 side and the one on the blue path

is pointing toward the number 1 side. If the number 1 side is at 2.8V

with respect to the number 2 then current will flow through that diode

on the green path. That's because current flows through a diode when

the diode is pointing at the side that's more negative (0V is more

negative than 2.8V). It flows from the positive to the negative (this

is conventional current, not electron flow current.)

But when the number 1 side is -2.8V, current will flow through

the diode on the blue path. That's because that diode will now be point

toward the side that's more negative (-2.8V is more negative than 0V.)

And that's how the diodes select which sub-circuit will be used.

Notice that the left side of the RC receiver also has two diodes

which operate in the same way.

Grounding problem

Why are there that mix of sub-circuits? The relay sub-circuits were

originally there because I needed a way to turn -2.8V into something

the Arduino can understand. But on the left side you can see that

I'm using a relay sub-circuit for handling 2.8V as well. Why didn't

I just use a simple analog sub-circuit as I did on the right side?

In fact, I did do just that originally. But that meant that both

sides of the RC receiver were connected to ground. In the above

diagram I've indicated the one place where there's a ground

connection going into the receiver, on the right side of the RC

receiver, and that there isn't a ground connection on the

left side. Having both sides connected to ground meant that those

two points of the RC receiver were connected together and that

caused weird outputs from the RC receiver overall.

Connecting those two points must

have interfered with whatever was going on in the circuit inside

the RC receiver itself.

So to avoid having a ground connection from the RC receiver on

the left side, I handled the positive 2.8V with another relay sub-circuit.

On the right side, the simple analog sub-circuit needs the connection

to the Arduino's ground because analog pin 1 expects the 2.8V voltage

to be relative to the Arduino's ground.

Lastly, you might ask why I didn't just use a relay sub-circuit instead

of the simple analog sub-circuit and have no ground connection to

the RC receiver. The reason is that I wanted to save

on the cost of a 4th relay.

The complete circuit

The complete circuit.

|

|

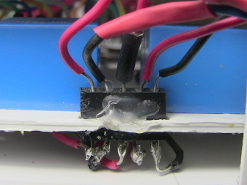

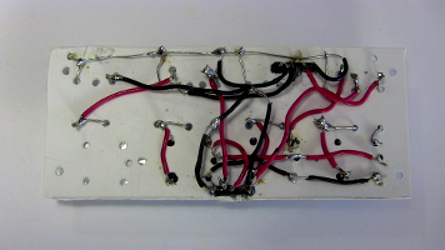

The follow is the resulting circuit board. Note that I didn't have enough

perf board so I drilled holes in some plastic and used that instead.

The back view below is the reverse left-to-right of the front view

since that's what happens when you flip it over to see the back.

I also drilled extra holes on the right side in case I ever want

to change the simple analog sub-circuit to also be a relay sub-circuit

instead (plus there are extra holes that turned out to be not needed.)

Front.

|

|

Back.

|

|

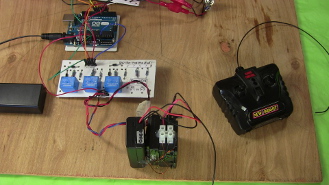

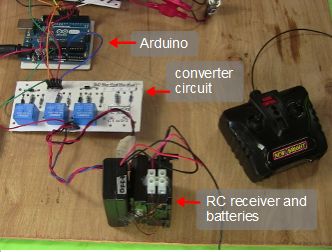

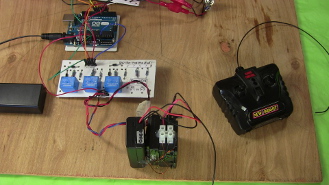

In the photo below the circuit is connected to the RC receiver on the

bottom and the Arduino on top. This was during the final testing of the

circuit before putting it in the BB-8. Note the use of female pin headers

for connecting to the rest of the circuit.

The circuit connected up.

|

|

Female pin header.

|

|

BB-8 (v2) Arduino code/sketch

The following code simply turns the motors on and off when the remote

control tells it to. There is no acceleration control, stabilization,

or anything else.

/*

BB-8 (v2) Arduino code

July 6, 2016 - Switched pins 5 and 6 to 3 and 11 to use the

lower PWM frequency (Arduino UNO). This is because I'm using

brushed motors, and unlike with brushless motors, the higher

the frequency, the worse it is for brushed motors.

Full details about this BB-8 droid can be found at:

http://rimstar.org/science_electronics_projects/bb-8_star_wars_droid_v2.htm

Drive motor circuits

--------------------

The two motors are driven independently and so there are two

Radio Controls (RC), one for each motor. Each one can turn

in two directions. A circuit exists between the RC receiver

and the Arduino to give the Arduino the following inputs:

rc1FwdPin - a digital pin indicating that motor 1 should be

turned on in the _forward_ direction (HIGH) or off (LOW)

rc1RvsPin - a digital pin indicating that motor 1 should be

turned on in the _reverse_ direction (HIGH) or off (LOW)

rc2FwdPin - an analog pin indicating that motor 2 should be

turned on in the _forward_ direction (value > 0) or off (0)

rc2RvsPin - a digital pin indicating that motor 2 should be

turned on in the _reverse_ direction (HIGH) or off (LOW)

Note that one of the pins above is an anlog pin simply to

save on the cost of one more relay. The relays were needed

as using analog for all of them meant problems with common

ground in the RC receiver.

The two motors are then controlled using two H bridge circuits.

Controlling each H bridge circuit is done by the Arduino by

turning on and off transistors using digital pins. There

are two transistors for each H bridge, one for each direction

the motor can turn. The motors each can turn

counter clockwise (CCW) or clockwise (CW) depending on which

transistor is turned on. Just which direction is called foward

and which is reverse is chosen arbitratily since the BB-8

doesn't really have a forward or reverse direction.

Pulse Width Modulation (PWM) is done to these pins for speed

control. The variables bridge1PWMduty, for motor 1, and

bridge2PWMduty, for motor 2, have the PWM values. 0 turns

the transistor/motor off.

The pins are:

bridge1CWPin - digital pin for motor 1 clockwise

bridge1CCWPin - digital pin for motor 1 counter clockwise

bridge2CWPin - digital pin for motor 2 clockwise

bridge2CCWPin - digital pin for motor 2 counter clockwise

Note that since it's a tank drive, to go forward one motor

must turn clockwise while the other motor turns counterclockwise.

*/

int bridge1CWPin = 9; // digital pin 9 for PWM

int bridge1CCWPin = 10; // digital pin 10 for PWM

int rc1FwdPin = 7; // digital pin 7, relay's switch

int rc1RvsPin = 8; // digital pin 8, relay's switch

int bridge1PWMduty = 48; // duty cycle for H bridge 1

// (a value of 25 blew a 1 amp fuse and

// 48 blew a 3 amp fuse but not a 5 amp fuse.)

int bridge2CWPin = 3; // digital pin 3 for PWM

int bridge2CCWPin = 11; // digital pin 11 for PWM

int rc2FwdPin = 0; // analog pin 0

int rc2RvsPin = 4; // digital pin 4, relay's switch

int bridge2PWMduty = 48; // duty cycle for H bridge 2

// (a value of 12 blew a 1 amp fuse and

// 48 blew a 3 amp fuse but not a 5 amp fuse.)

void turnMotor1Off()

{

analogWrite(bridge1CWPin, 0); // off

analogWrite(bridge1CCWPin, 0); // off

}

void turnMotor1CW()

{

analogWrite(bridge1CWPin, bridge1PWMduty); // PWM duty cycle

analogWrite(bridge1CCWPin, 0); // off

}

void turnMotor1CCW()

{

analogWrite(bridge1CWPin, 0); // off

analogWrite(bridge1CCWPin, bridge1PWMduty); // PWM duty cycle

}

void turnMotor2Off()

{

analogWrite(bridge2CWPin, 0); // off

analogWrite(bridge2CCWPin, 0); // off

}

void turnMotor2CW()

{

analogWrite(bridge2CWPin, bridge2PWMduty); // PWM duty cycle

analogWrite(bridge2CCWPin, 0); // off

}

void turnMotor2CCW()

{

analogWrite(bridge2CWPin, 0); // off

analogWrite(bridge2CCWPin, bridge2PWMduty); // PWM duty cycle

}

void setup()

{

pinMode(bridge1CWPin, OUTPUT);

pinMode(bridge1CCWPin, OUTPUT);

pinMode(bridge2CWPin, OUTPUT);

pinMode(bridge2CCWPin, OUTPUT);

turnMotor1Off();

turnMotor2Off();

//Serial.begin(9600); // for sending debugging messages

}

boolean debounce(boolean last, int switchPin)

{

boolean current = digitalRead(switchPin);

if (last != current) {

delay(5);

current = digitalRead(switchPin);

}

return current;

}

int rc1FwdValPrev = LOW;

int rc1RvsValPrev = LOW;

int rc2FwdValPrev = 0;

int rc2RvsValPrev = LOW;

void loop()

{

int rc1FwdVal = 0;

int rc1RvsVal = 0;

int rc2FwdVal = 0;

int rc2RvsVal = 0;

/*

* Handle Motor 1

*/

// get the relay's switch position

rc1FwdVal = debounce(rc1FwdValPrev, rc1FwdPin);

//Serial.print("1F:");

//Serial.println(rc1FwdVal);

if (rc1FwdValPrev != rc1FwdVal) {

// the switch position changed

rc1FwdValPrev = rc1FwdVal;

if (rc1FwdVal == HIGH) {

// the relay was turned on

turnMotor1CCW();

} else {

// the relay was turned off

turnMotor1Off();

}

}

// get the relay's switch position

rc1RvsVal = debounce(rc1RvsValPrev, rc1RvsPin);

//Serial.print("1R:");

//Serial.println(rc1RvsVal);

if (rc1RvsValPrev != rc1RvsVal) {

// the switch position changed

rc1RvsValPrev = rc1RvsVal;

if (rc1RvsVal == HIGH) {

// the relay was turned on

turnMotor1CW();

} else {

// the relay was turned off

turnMotor1Off();

}

}

/*

* Handle Motor 2

*/

rc2FwdVal = analogRead(rc2FwdPin);

//Serial.print("2F:");

//Serial.println(rc2FwdVal);

if (rc2FwdVal > 0 && rc2FwdValPrev == 0) {

turnMotor2CW();

rc2FwdValPrev = rc2FwdVal;

} else if (rc2FwdVal == 0 && rc2FwdValPrev > 0) {

turnMotor2Off();

rc2FwdValPrev = 0;

}

// get the relay's switch position

rc2RvsVal = debounce(rc2RvsValPrev, rc2RvsPin);

//Serial.print("2R:");

//Serial.println(rc2RvsVal);

if (rc2RvsValPrev != rc2RvsVal) {

// the switch position changed

rc2RvsValPrev = rc2RvsVal;

if (rc2RvsVal == HIGH) {

// the relay was turned on

turnMotor2CCW();

} else {

// the relay was turned off

turnMotor2Off();

}

}

delay(50);

}

Alternatives to relays - using opto-isolators

A problem with relays is that they require the coil to be energized

for the entire time that the switch is to be closed (closed for a

normally-open relay, or open for a normally-closed relay.) An alternative

may be to use an opto-isolator in place of each relay. I haven't tried

it myself, and have never worked with opto-isolators so I don't know

how well it would work and what the limitations or issues would be.

But it's an alternative to explore.